Multi-purpose ecological air cooled system

بررسی اجمالی:

Low consumption WinPOWER EXP

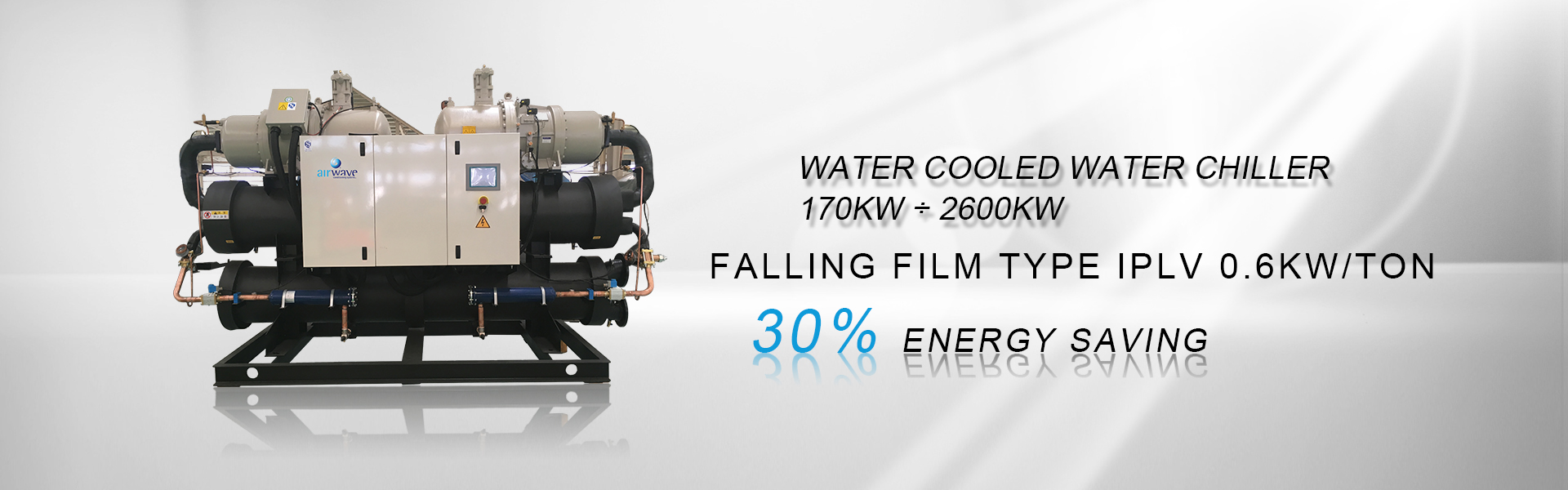

TXAEY 4400÷6660

Cooling capacity: 362÷650 kW Heating capacity: 404÷704 kW

Plus Product

Multi-purpose Class A units with TER up to 7.9

Extended operating limits

Units for 2, 4 and 6-pipe systems

معرفی محصول:

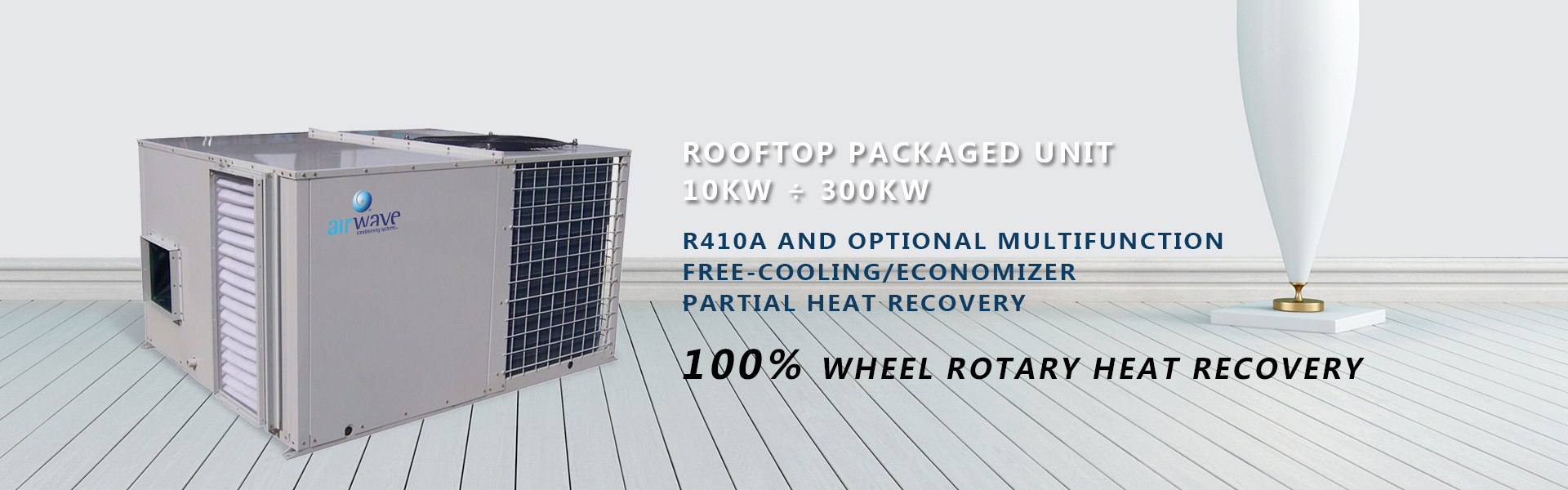

\EXP systems – Multi-purpose ecological air-cooled system with axial fans. Range with hermetic Scroll compressors and R410A refrigerant gas.

Construction features

• Compressor: scroll type, rotary, hermetic complete with thermal protection and casing heater.

• Up to 6 capacity steps with high efficiency at partial loads.

• Main and secondary heat exchangers: crossed flow stainless steel plate exchangers, complete with antifreeze heater, closed cell polyurethane foam rubber insulation and water flow differential pressure switch.

• Air side heat exchanger: finned coil with copper pipes and aluminium fins.

• Fan: external rotor axial type electric fans, equipped with internal thermal protection, accident protection grilles and a proportional electronic device for continuous fan rotation speed regulation (T version; fans with an EC motor are standard in the Q version)

• Control: microprocessor electronic control with Adaptive Function Plus logic.

• Structure: load bearing structure made of galvanised sheet steel and painted with polyester powders.

• The unit is also complete with:

– fan and compressor circuit breaker switches, heat exchanger antifreeze heater;

– display of cooling circuit high and low pressure;

– electronic expansion valve;

– clock board.

Versions

• T – High efficiency version.

• Q – Supersilenced version complete with soundproofed compressor technical compartment, super-low fan speed fans with EC motor.

Models

• TXAETY: EXPsystems unit.

• TXAEQY: supersilenced EXPsystems unit.

Factory fitted accessories

• Shell and tube main and secondary heat exchangers.

• PUMP with single or double electric pump, including an automatic pump in standby. The electric pumps are available in the main and secondary/recovery heat exchanger low or high head set-ups.

• TANK&PUMP with 700-1000 litre integrated buffer tank (depending on models) and single or double electric pump, complete with expansion tank, air vent valves, safety valve and water side pressure gauge.

• Desuperheater.

• -15°C condensing control with fans with EC motor (standard in the Q versions).

• Condensing control with over-pressure fans (T version only).

• Power factor correction capacitors (cosφ > 0.94).

• Forced limit of power consumption.

• Forced noise limit.

• Energy parameters measuring device.

• Optimised energy efficiency.

• Soft starter.

• Compressor box and soundproofed cooling circuit.

• Compressor soundproof enclosures.

• Cooling circuit delivery and intake valves.

• Refrigerant leak detector.

• Cooling circuit high and low pressure gauges.

• Double safety valves.

• Coil protection nets or metal filters.

• Bottom compartment protection nets.

• Copper/pre-painted aluminium or copper/copper coils.

• Digital input for double set-point.

• 4-20 mA analogue input for shifting set-point.

• Electrical panel antifreeze heater, buffer tank, electric pumps and desuperheater, if present.

• Interfaces for serial communication with other devices.

• Spring anti-vibration mounts.

Separately supplied accessories

• Remote keyboard with display.

• Thermostat with display.

• airwave supervisors for unit monitoring and remote management.

• airwave sequencer for integrated management of several water chillers.

Data at the following conditions:

❶ Air: 35°C – Water: 12/7°C.

❷ Air: 7°C D.B. – 6°C W.B. – Water: 40/45°C.

❸ In open field (Q = 2) at 10 m from the unit.

❹ Evaporator water: 12/7°C. Recovery output water 45°C – Nominal flow rate.

❺ Total sound power level in dB(A) based on measurements carried out in accordance with regulation UNI EN-ISO 9614.

❻ Weight refers to the unit when empty.

(◊) In Average climatic conditions, low temperature application

(§) Seasonal energy efficiency: low temperature heating in Average climate (EU Regulations N°811/213 and N°813/2013)